Production

Here are the processing steps of our leathers (coming only from selected farms):

- Soaking: to return the raw hides on the original condition.

- Fleshing: to eliminate the excess fleshing.

- Splitting: to separate the upper layer, said grain or skiver, from the flesh or split

- Shaving: to eliminate the remaining grain from flesh

- Tanning 100% fish oil: to give the skins softness, absorption and durability, and the characteristic colour-smell.

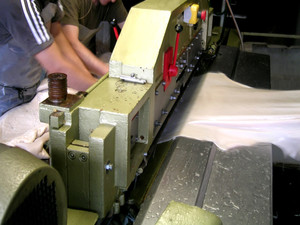

- Buffing by hand on both sides: to give the velour effect

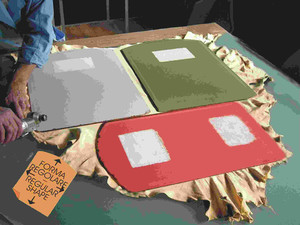

- Cutting with use of templates: to ensure shape and size.

- Packaging

The work is performed by people of high experience, with suitable machinery, completely in our tannery in Cuneo-Italy, getting a natural product of high quality, respectful of all European standards and laws, and 100% Made in Italy.